China CNC milling service is a viable solution for producing accurate and quality parts. Chinese manufacturers use modern CNC machines and qualified operators to achieve a fast, precise, and consistent result. Besides this, China offers economical and standard quality solutions, whether you need prototypes or complete production runs.

With the appropriate service, you receive access to the latest machines, multi-axis services, and a broad selection of materials. This guarantees your parts are within tight tolerances and keeps complicated shapes with minimal design challenges.

Chinese manufacturing companies are not merely a professional that simply cuts metal. They save your time and expenses, and provide parts that are to your perfect specifications.

How an Online CNC Machining Service in China Operates Efficiently

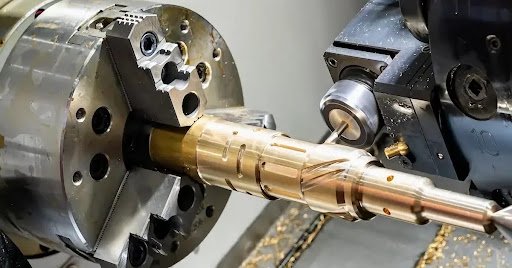

China’s CNC milling service uses accurate computer-controlled tools to cut a material out of a workpiece. The technology helps provide the same results and reduces errors, which is essential in modern production.

Manufacturing companies employ 3, 4, or 5 axes for complicated geometries. Each axis provides flexibility with angled cuts, multiple surfaces, and contours. This assists you in machining parts of metal that would have been nearly impossible to do manually.

They also offer broad range of material choices, including metals and plastics. You can combine skilled operators with the milling technology to ensure you get high-quality and repeatable results each time.

3-Axis CNC Milling

3-axis CNC Milling

3-axis CNC milling moves in three planes, like X, Y, and Z. It is suitable for flat surfaces and simple geometries. This is usually employed with prototypes and standard parts.

It enables accurate cuts, and the setup is not complicated. 3-axis milling is affordable on the majority of simple parts.

4-Axis CNC Milling

4-axis CNC Milling

A rotating axis supplements the process. It is possible to machine several sides without repositioning the workpiece. This saves time and minimises alignment errors.

It is suitable for components such as housings or cylinders. The additional axis enables deeper cuts and more accurate geometries. A sensible option for such an approach is medium-complexity projects.

5-Axis CNC Milling

5-axis CNC Machining

5-axis milling runs in 5 directions in a single pass. One setup can be used to produce complex forms and angled surfaces. It does not have to undergo several repositioning processes, which wastes time.

It is ideal for aerospace, car, and medical components. You obtain complicated designs, excellent precision, and good surface finish. This will be the most efficient and minimise errors.

Raw Materials Used by CNC Machining China Companies

China CNC milling service serves metals, plastics, and composites. Choosing the right material has made the parts act as desired.

Aluminium is light in weight and highly resistant to corrosion. It is perfect for aerospace, electronics, and lightweight housings. Stainless steel is strong and rugged and can be used in the food and medical components industries. Titanium contains high strength and low weight characteristics of high-performance components.

Plastic and engineered composites provide resistance to wear or chemicals. You can produce complicated forms without the added weight. Reinforced carbon composites are strong and stable in structure.

Aluminium Components

Aluminium is simple to machine, and it yields reproducible results. CNC milling provides finishes and accurate dimensions. It can be used in prototypes and complete production lines.

Stainless Steel Components

Stainless steel is resistant to pressure and temperature. CNC milling is done to make every part meet strict tolerances. It is applied in industrial, medical, and durable goods.

Plastics and Composites

Plastics and composites are lighter and wear-resistant. Plastic CNC milling permits acceptable forms and flat surfaces. They are suitable for housings, enclosures, and working prototypes.

Advanced China CNC Milling Service Techniques for Complex Parts

Selecting an appropriate milling method influences efficiency, surface quality, and tool life. China CNC milling service presents traditional and advanced procedures to achieve the best.

The feed’s proper direction and chip removal enhance surface finish. An appropriate technique also prolongs the life of the tools and minimises the machine downtimes. You know such techniques, which means you guarantee quicker and precise manufacturing.

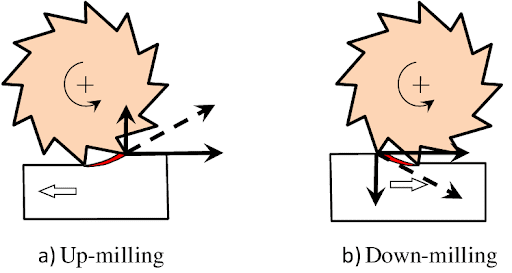

Up Milling (Direct Milling)

Up milling slides the workpiece opposite to the rotation of the cutter. Chips are thin and become thicker towards the cut. It uses additional cutting power and cuts heavy material.

The workpiece can be lifted, and thus it needs to be firmly fixed. The technique is best for working with hard metals such as steel or bronze. It eliminates in huge volumes.

Down Milling (Climb Milling)

Up Milling Vs Down Milling Illustration

Down milling involves the movement of the workpiece in the same direction as the cutter. It forms shorter chips, lowers friction levels, and refines a surface.

The cut is stabilised using the downward tangential forces. This process is ideal for the completion of soft metals like aluminium. It enhances the feed rates without compromising the precision.

Slot Milling

Slot milling cuts patterns in a workpiece. Choosing the appropriate cutter width will help avoid damage to adjacent surfaces. It is possible to make keyways, ventilation slots, or functional channels.

Form Milling

Form milling is used to cut parts into complicated lines or outlines. Special cutters make unique patterns, curves, or threads. It enables complex designs without post-processing.

Side Milling

Side or vertical edge, Side milling machines. The cutter is moved at right angles to its axis to produce proper surfaces. It is perfect with brackets, housings, or structural elements.

China CNC Milling Applications

China CNC milling service applies to various industries, so you can easily gain accurate results.

CNC milling in aerospace produces engine parts, brackets, and structural parts. A car has housings, an engine, and precisely toleranced custom components. CNC-milled surgical equipment, implants, and patient-specific components are helpful in medical devices.

Gears, moulds, and mechanical components are needed in industrial machinery. CNC milling is very durable and precise. CNC milling is also essential to consumer goods like electronic enclosures, housings, and functional prototypes.

Selecting a Reliable CNC Milling Service in China

When choosing a CNC milling partner in China, it is necessary to consider the expertise, machinery, and quality control. Well-trained staff will ensure your parts are in tight tolerances and on time.

The multi-axis cutting of complex designs is possible using advanced machines. The processes of quality assurance reduce the number of defects and increase uniformity. Open communication ensures your project is not lost track and adheres to the design requirements.

Summary

China CNC milling service provides quality solutions that are accurate, reliable, and affordable. You can manufacture aerospace, automotive, medical, industrial, and consumer components. Competent operators, modern machines, and flexible materials enable you to attain close tolerances and intricate designs.

The selection of the appropriate service guarantees the quality of parts, productive output, and waste reduction. With knowledge of the CNC milling methods and the materials available, you can achieve the same results as the prototype and the full-scale production requirement. China CNC milling gives you the speed, precision, and consistency you need in your projects.