Let’s be honest, the way companies do business together has fundamentally shifted. Additive manufacturing didn’t just arrive on the scene; it kicked down the door and changed everything about how organizations connect, work together, and stay competitive. Remember when traditional manufacturing meant you needed deep pockets just to get started? Those days are gone.

Entry-level 3D printer shipments surged by 35% year-over-year in Q4 2023, which tells you something important: businesses of every size now have access to production tools that used to belong exclusively to industrial giants. But here’s what makes this truly fascinating, this isn’t just about manufacturing differently. We’re watching entire supply chains get rewritten and unexpected partnerships from across industries that never talked to each other before.

How Additive Manufacturing Is Revolutionizing Supply Chain Partnerships

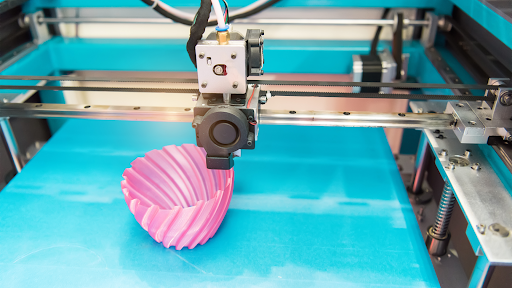

Now that the business impact of 3D printing has become undeniable, the most dramatic changes are happening in supply chain management and inventory control. 3D printing technologies like FDM, SLA, and SLS aren’t experimental anymore, they’re the backbone of how modern companies operate, letting you innovate faster and pivot when markets shift without warning.

On-Demand Production Networks Are Killing Traditional Inventory

Think about all those warehousing nightmares just-in-time manufacturing has eliminated. You produce parts exactly when you need them, slashing storage expenses. Digital inventory systems now link 3d printing companies across continents, turning their combined capabilities into virtual warehouses that store files instead of physical stock until someone hits “print.”

For businesses searching for 3d printing services near me, this interconnected model means faster access to parts, less downtime, and a smoother supply chain. The automotive sector jumped on this aggressively. Manufacturers keep design files on servers instead of parts on shelves, printing components across distributed facilities whenever demand appears. This strategy has carved significant chunks out of inventory carrying costs while speeding up response times dramatically.

Local Manufacturing Hubs Are Building Stronger Regional Networks

Regional production centers are multiplying fast, creating tighter local business ecosystems you can actually rely on. These hubs slash shipping distances, cutting both your costs and environmental impact.

For companies seeking flexible and efficient manufacturing solutions, these emerging local networks deliver reliable, quick production options right in their backyard, sparking partnerships that simply couldn’t exist when everything required overseas shipping and weeks of transit time.

Local production changes the game. Faster turnarounds, easier quality checks. When your manufacturing partner sits across town instead of across an ocean, collaboration stops being a logistical headache.

Attracting and Keeping Clients Through Customized 3D Printing

Beyond warehouse optimization, this digital inventory revolution is building regional manufacturing strength in ways nobody predicted. Companies leveraging 3D printing aren’t just streamlining operations—they’re completely reimagining client relationships.

Mass Customization as Your Secret Weapon

Mass customization without insane costs? It’s real now. You can offer personalized products without the traditional financial penalties that made custom work prohibitively expensive. Design modifications happen in real-time during client meetings, turning their feedback into updated prototypes in hours, not weeks.

This builds fierce brand loyalty. Give customers exactly what they envision, and they’ll keep coming back. Businesses in communities like Tualatin, Oregon, have built entire business models around providing custom 3d printing near me as their primary offering, letting clients touch and adjust prototypes hands-on before committing to full production runs.

Rapid Prototyping That Keeps Clients Engaged

Speed attracts clients initially, but it’s what keeps them invested long-term. Shipments of professional 3D printers ($2.5-$20K) plummeted 32% as companies sought cheaper alternatives amid sticky inflation, pushing businesses toward service providers rather than buying equipment outright.

This created explosive demand for online 3d printing services, letting you outsource rapid prototyping and development without massive upfront capital expenditures, compressing development cycles from months into days and handing your team a serious competitive edge.

Digital Platforms Bridging Businesses and Manufacturing Networks

Accessing these advantages requires sophisticated digital platforms that connect you with specialized printing capabilities worldwide. These marketplaces have revolutionized how companies discover and collaborate with manufacturing partners.

B2B Marketplace Ecosystems for Additive Manufacturing

Platforms like Xometry, Shapeways, and Hubs built entire ecosystems around additive manufacturing. Their automated quoting returns price estimates in minutes instead of days. Real-time production scheduling shows you exactly when capacity opens across their networks.

Quality assurance has reached impressive consistency levels. Certifications and third-party testing let you confidently order from vendors you’ve never worked with before.

Subscription-Based Models for Ongoing Partnerships

One-off orders are fine for testing the waters, but smart companies lock in advantages through recurring partnership structures. Monthly part quotas establish stable manufacturing relationships benefiting everyone involved.

Priority access to cutting-edge 3d printing technologies frequently comes through these subscription arrangements, giving you an edge in quality and capacity when demand spikes.

Dedicated account management and design support transform transactional interactions into strategic partnerships. You get consistent quality and preferential treatment when everyone’s scrambling for capacity.

Taking Action on Manufacturing Innovation

The transformation of business relationships through additive manufacturing is just beginning. Companies embracing these technologies now, whether through leveraging online 3d printing services or developing in-house capabilities, position themselves at the forefront of modern manufacturing networks.

Geographic barriers are crumbling fast. Collaboration opportunities are exploding everywhere you look. Smart businesses experiment, adapt, and grow accordingly. The real question isn’t whether 3D printing will reshape your industry’s business connections. It’s whether you’ll lead the innovation wave, or spend the next decade scrambling to catch up while your competitors pull ahead.

FAQs on 3D Printing Business Connections

- How can small businesses find reliable providers for custom projects?

Research online marketplaces like Xometry or Hubs that vet vendors and guarantee quality. Check reviews, request sample parts, and start with small test orders before committing to larger production runs or long-term partnerships.

- What are the cost differences between in-house printing versus outsourcing?

In-house equipment requires significant capital investment ($2,500-$100,000+), plus materials, maintenance, and operator training. Outsourcing eliminates upfront costs but charges per-part premiums. Break-even typically occurs around 500-1,000 annual parts, depending on complexity.

- Which technologies work best for different business applications?

FDM suits functional prototypes and fixtures. SLA delivers smooth surfaces for presentation models. SLS produces durable end-use parts without support structures. Metal printing serves aerospace and medical applications requiring strength and biocompatibility.